DATA CENTER

INTRODUCTION

Data Center are mission critical infrastructure. In todays time protecting and securing data is of outmost important. Data Center have inherent challenges. These challenges are countered by 100s of sensors integrated with Data Center management systems. This confluences of decentralised sensors are ineffective, expensive and donot predict critical calamities or prevent threat. For this Mission critical infrastructure advanced photonic systems is required that will not only protect, prevent and predict the threats but at a same time reduce costs of operations.

ATTRIBUTE

Gases causing contamination.

- Particulate and gaseous contaminants can be detrimental to the sensitive electronic and electronic devices used in IT esp PCB.

- The failure of information technology (IT) equipment is exclusively caused by pollutants such as :-

- Sulfur and Nitrogen oxides (SOx, NOx),

- Hydrogen (H2) Hydrogen sulfide (H2S), ozone (O3), chlorine (Cl2),

- Diesel particulate matter (DPM),

- AUM_Iaq monitors all types of contamination on continues and real time basis.

- A single unit of AUM_IAQ for data center covers 100 sq. mt. of space.

- Based on interior layout and design of hot and cold aisle AUM_IAQ can be installed.

Particulate and gaseous contamination guidelines for data centers (ASHRAE 2011)

- Data centers must be kept clean to ISO 14644-1 Class 8 (ISO 2014). This level of cleanliness can generally be achieved by an appropriate filtration scheme

- Sources of dust inside data centers should be monitored and reduced. Every effort should be made to filter out dust that has deliquescent relative humidity greater than the maximum allowable relative humidity in the data center.

- Gaseous contamination should be within the ISA-71.04-2013 severity level of G1-Mild that meets :

- A copper reactivity rate of less than 300 angstroms per month, and

- A silver reactivity rate of less than 200 - per month.

- For data centers with higher gaseous contamination levels, gas-phase filtration of the inlet air and the air in the data center is highly recommended.

AUM_IAQ Monitors Fine and ultrafine particulate matter (PM2.5, PM0.1)

- Although less of a problem than gaseous contaminants, particulate matter has come under increased scrutiny (Singh et al. 2015).

Most attention is being paid to the fine particles (<2.5m), of which there are of two types. - Primary particles are directly emitted from a source.

- Secondary particles, which comprise the bulk of the fine particulate pollution, are those formed as a result of chemical reactions in the atmosphere.

- SO2 and NO2 can interact with <0.1 m carbonaceous material seed particles in a complex, multi-step photochemical process to produce sulfuric and nitric acids.

- The presence of ozone, a contaminant increasing in both outdoor levels as well in regional coverage, serves to catalyze these reactions.

Combating the limitation of conventional Sensors

Limitations of two of the most widespread tools used for airflow measurements i.e. balometers and anemometers are overcome by AUM_IAQ

- No routine calibration required for photonic sensors.

- No back-pressure compensation algorithms :-

- Algorithms cant fully compensate for the high differential pressures and high flow rates to produce an accurate Cubic Feet per Minute (CFM) value.

- No confluence of sensors required at various breadth and height of racks.

- No assumption regarding uniform velocity :-

- Extrapolation of CFM from panel velocity contains another substantial assumption?that velocity is uniform across the entire surface area of the airflow panel.

- No constraints with respect to type of airflow panels

- Perfs, high-flow grates, panels with/without dampers.

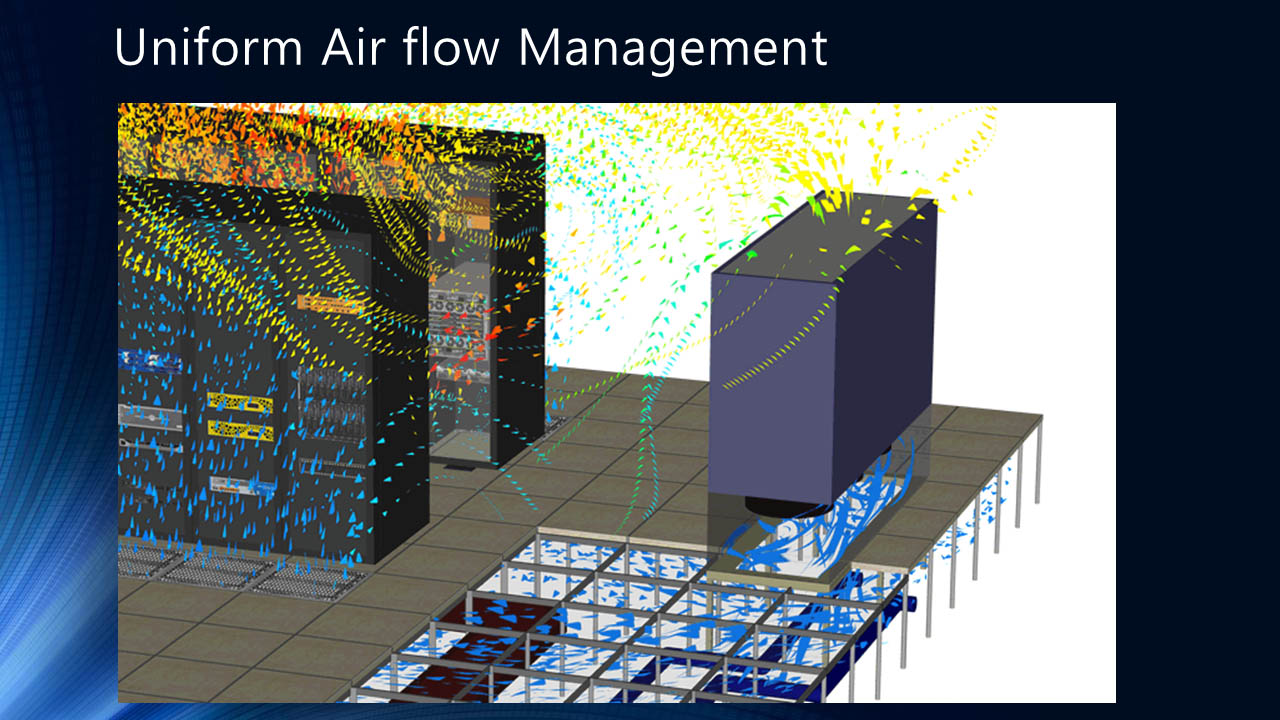

Air Dynamics

- Air flow management is the most ingredient aspect of Data center.

- A perfect Air flow management is dictated by the correctly monitored parameter of Air :-

- Temperature

- Velocity

- Humidity and

- Direction

- One unit AUM IAQ can monitor flow of hot air and cold air in the Servers gangway i.e. 20ft. Length * 10ft of height.

- As per requirement heat pockets of each server can also be monitored.

- Hot / Cold pockets can be plotted on Computational Fluid dynamic analysis.

- AUM_Fire is extremely sensitive that captures release of smoke even from cigarette. With clear line of sight, distance to monitor fire or smoke is not a limiting factor.

- A building fire can lead to serious consequences - even a small fire can grow in seconds unless quickly suppressed.

- Fire and security systems are critical to site safety.

- Photonic systems can help ensure proper evacuation and limit the spread of fire, reducing damage and increasing the safety of personnel.

- The severity of smoke or fire is predicted by AUM based photonic system and Array of things on increase in concentration.

- AUM qualifies and quantifies the gas. Based on concentration of gas, information is sent to command and control system.

- Laser light will travel to the source of fire or smoke, rather than waiting for smoke to reach the sensor.

Battery Room

- Backup batteries are normally of the lead acid type, however some are liquid based, gel cells, or even sealed type batteries.

- No matter which of these battery types they are, hydrogen is generated while being discharged and recharged. Hydrogen is a highly flammable gas.

- Hydrogen concentrations of 4% to 75% by volume in air are potentially explosive.

- This danger can be eliminated by monitoring for a hydrogen buildup and taking appropriate action if a build up occurs.

- The easy to install and cost effective AUM IAQ hydrogen detection and monitoring of H2 gas and relays for remote connection to alarm/monitoring systems and for control of external relays or an exhaust fan.

ENABLER

Advantage of precise Air Flow monitoring

- Continues Air flow Temperature & Humidity monitoring is possible at different location.

- Parameters required for CFD analysis is available every second.

- Precise and sensitive measurement will lead to proper energy management of HVAC.

- Demand by customer for minimum and uniform CFM airflow from panel at different heights of rack can be provided in scientific & credible manner.

- While AUM_IAQ Photonic System is monitoring AIR flow and its parameter it is also monitors AIR QUALITY.

- The AUM_IAQ Photonic System is unique in monitoring the entire structure of air and the rate of volume of air no such system exists as of today.

CATS total solution is also comprised of Internet-connected devices, equipment, sensors, digital signs & menu boards, premises

- All of these smart 'things' have unique identifiers and can automatically transmit data across a network.

- Frequent continuous evaluation of the health of equipment throughout its serviceable life. Condition and Vibration (VIDUR) monitoring can, in many cases, be extended to provide primary protection, but its real function will always be to attempt to recognise the development of faults at an early stage.

- This data can be analyzed to improve operational efficiency, productivity, marketing, resource utilization, security, employee and customer safety & experience.

- As CATS SMART AoT solutions becomes more sophisticated, use cases will drive sales, service and operational improvements sector wise.